Refer to the official website for the latest syllabus and updates.

Instructions for the Patent Agent Examination 2016 – Paper II :

1. This paper consists of 3 parts- Part A (20 marks), Part B (30 Marks) & Part C (50 marks).

2. ALL questions in Part A and B are compulsory.

3. Part C comprises Part Cl (20 Marks) and C2 (30Marks). Part Cl consists of 2 questions and the candidate is required to answer any 1 of them. Part C2 also consists of 2 questions and the candidate is required to answer any 1 of them.

4. In case a candidate answers more questions than required, the first attempted question will be evaluated.

5. Candidates should read the questions very carefully before answering.

6. No clarification will be provided during the course of the examination.

7. There is no negative marking.

8. Total Marks: 100

9. Time: Three hours

PART A

4 x 5 M =20 marks (4 questions)

Q.1 A and B are co-inventors of a tracking device. Later A files an application for a patent in his own name. B comes to know about this fact from the Journal of the Patent office. What action B can take to redress this injustice inflicted upon him by A?

Q.2 Y owns an Indian Patent. X requests for a licence under the patent from Y.Y imposes certain conditions such that X cannot acquire such articles which are not covered by the Patent from any person other than Y. Y also imposes a condition of exclusive grant back in the licence. As an agent do you think these conditions are appropriate? Please give your answer vis-a-vis the relevant provisions of the Patents Act.

Q.3 An inventor/applicant has filed an application for patent in India and approaches you immediately thereafter for filing international application under PCT with specific questions on following:

a) Whether he can claim priority of his application filed in India and within what time.

b) When he can file a national phase application from PCT route.

c) After filing of national phase application, what would be fate of his previous application?

Please advise him as per provisions of PCT and Indian Patents Act.

Q.4 Write a short note on the benefits provided for startups and small entities under the Patents Rules.

Part B

3X10 M=30 Marks (3 questions)

Q.5 Section 3(d) of Indian Patents Act, 1970 was amended which includes an explanation as follows:

“For the purposes of this clause, salts, esters, ethers, polymorphs, metabolites, pure form, particle size, isomers, mixtures of isomers, complexes, combinations and other derivatives of known substance shall be considered to be the same substance, unless they differ significantly in properties with regard to efficacy;

Explain the term “efficacy” in the light of the judgment of Supreme Court and other relevant orders by different courts in the matter of Novartis vs Union of India involving an anti-cancer compound.

Q.6 A invents a medicine which is a combination of components A, B and C. Component C is a powder of herb which occurs in hilly terrain of Assam and adjoining areas. As a Patent agent advise him regarding the essential procedural and substantial aspects of patenting of such combinations.

Q.7 A patent was granted to X on a communication system. After getting the patent X serves a notice of infringement upon Y on the ground that he was infringing the patent granted to X. Y approaches you for suitable advice. Please explain to Y the remedies under the Patents Act.

Part C

Part C1 consists of 2 questions and the candidate is required to answer any 1 of them.

Part C2 also consists of 2 questions and the candidate is required to answer any 1 of them.

In case a candidate answers more questions than required, the first attempted question will be evaluated.

Part C1

After reading the specification:

i. Provide an appropriate title,

ii. Draft an abstract (maximum of 150 words) and

iii. Draft 5 claims

1X 20 M = 20 marks

Q.8

The invention is generally related to the field of formulation and use of fertilizer compositions for agricultural use. More specifically, the invention relates to fertilizer compositions that contain viable Bacillus bacteria and decontaminated animal manure. It is well understood that nitrogen (N), the single most important plant nutrient, has been over used in modern agriculture in an effort to encourage maximum plant yields. Nitrogen in the form of soluble nitrates is particularly harmful to the environment since nitrates readily leach out of soil and cause pollution of ground and surface waters. One of the principal goals of agricultural science has been to invent a perfect fertilizer composition that is capable of optimizing food plant production when used at minimum application rates and that, subsequently, will not degrade or adversely affect the soil ecosystem. The present invention attains this goal.

Prior art X, claims a biochemical fertilizer but no mention is made of using decontaminated manure as a source of the organic ingredients. Other non-manure organics are indicated. A broad list of microorganisms, listed by genera, is claimed in claim 10, which includes Bacillus, but this claim simply lists all the genera that may contain beneficial microorganisms, not novel as they are listed as such in numerous textbooks, and does not give any specific examples of species with performance data. The need for microbial nutrients is mentioned in claim 14 but these must be part of the microorganism ingredient, not the bulk organic ingredient as in my invention (where decontaminated manure feeds the Bacillus).

There is a great but heretofore unmet need worldwide for technology that permits lower use rates of N while maintaining plant yields. The present invention provides such technology by combining unique ingredients and processing them in such a way as to arrive at potentiated fertilizer compositions capable of effecting substantial benefits in plant production. The novelty of the present invention relates to specific synergisms between the various ingredients and to the processing technology that renders such ingredients functional. In accordance with the present invention, fertilizer compositions that contain viable Bacillus bacteria and decontaminated animal manure are presented. Optionally, these formulations preferably also contain humic acid and N—P—K substances, where N means nitrogenous or nitrogen-containing compounds (organic or inorganic), P indicates phosphorous- containing (organic or inorganic compounds), and K indicates potassium-containing (organic or inorganic compounds). More specifically, the invention concerns compositions comprising at least one species of probiotic Bacillus bacteria that exert a positive effect on the yield of agricultural plants and/or reduce the nitrogen requirements of agricultural plants, and animal manure that has been decontaminated to reduce the concentration of undesirable microorganisms.

Thus, a first aspect of the invention is a fertilizer composition for plant production comprised of decontaminated manure and Bacillus spores, and preferably humic acid and, optionally, one or more of N compounds, P compounds, K compounds, and combinations of two or more of these compounds (for example two N compounds, an N compound with a P compound, two K compounds, or one each of N compound, P compound, and K compound). Preferred compositions are those wherein the ingredients are blended into an admixture resulting in a granular product. Other preferred compositions are those blended into an admixture resulting in a powdered product. Preferably, the ingredients are formed into hardened pellets. The decontaminated manure is preferably derived from manure selected from the group consisting chicken or swine manure, particularly produced without litter or bedding, and produced from animals not receiving growth-promoting antibiotics in their feed. Other preferred compositions of the invention are those wherein the Bacillus spores are from strains of probiotic Bacillus bacteria capable of enhancing beneficial microbial populations within the rhizosphere. Preferably, the decontaminated manure has a total aerobic/facultative viable plate count reduced by 2-4 logs (100 to 10,000 times) compared to raw manure. Yet other preferred compositions of the invention are those wherein the humic acid is derived from lignite.

As used herein, “humic acid” means a polymeric compound typically containing the brownish-black pigment melanin, and can be obtained from lignite. It is soluble in bases, but insoluble in mineral acids and alcohols. It is not a well-defined compound, but a mixture of polymers containing aromatic and heterocyclic strictures, carboxyl groups, and nitrogen, and is used in drilling fluids, printing inks, and plant growth. See Hawley’s Condensed Chemical Dictionary, 12th Edition, (1993), page 608. As seen in the examples herein, not all humic acids behave in similar fashion. Still other preferred compositions of the invention are those wherein the N compounds are selected from the group consisting of urea, ammonium sulfate, ammonium nitrate, ammonium phosphate, calcium nitrate, potassium nitrate, sodium nitrate; the P compounds are selected from the group consisting of ammonium phosphate, superphosphate, Ca(H2P04)2, tricalcium phosphate, phosphate salts of sodium or potassium, including orthophosphate salts; and the K compounds are selected from the group consisting of KCI, potassium sulfate, potassium nitrate, and phosphate salts of potassium, including orthophosphate salts.

Preferred compositions of the invention are those wherein the decontaminated manure has a total aerobic/facultative viable plate count reduced by 2-4 logs (100 to 10,000 times) compared to raw manure. Still other preferred compositions of the invention are those wherein the N compounds are selected from the group consisting of urea, ammonium sulfate, ammonium nitrate, ammonium phosphate, calcium nitrate, potassium nitrate, sodium nitrate; the P compounds are selected from the group consisting of ammonium phosphate, superphosphate, Ca(H2P04)2, tricalcium phosphate, phosphate salts of sodium or potassium, including orthophosphate salts; and the K compounds are selected from the group consisting of KCI, potassium sulfate, potassium nitrate, and phosphate salts of potassium, including orthophosphate salts.

Decontaminated manures are prepared by methods known in US patent zzzz. The fertilizer is prepared by mixing decontaminated manures and other ingredients as discussed above and a suitable amount Bacillus spores. Preferred compositions of the invention are those wherein the decontaminated manure has a total aerobic/facultative viable plate count reduced by 2-4 logs (100 to 10,000 times) compared to raw manure.

This invention relates to new and useful improvements in lawn sprinklers, and has as its principal object. The provision of a lawn sprinkler comprising a sprinkler head mounted on a wheeled frame and attached to a pressure water supply; and having means operable by the pressure of the supply water to propel said wheeled frame over the ground.

Another object is the provision in a lawn sprinkler of the character described wherein the sprinkler head rotates to distribute water evenly over a wide area, and wherein said propelling means operates mechanically from the rotation of said head.

A further object is the provision of a lawn sprinkler of the class described wherein said propelling means operates by traction in an elongated member, which may be the water supply hose; laid out on the ground. The frame is steerable, so as to follow the elongated member around curves. Other objects are simplicity and economy of construction, efficiency and dependability of operation, and adaptability for uses other than the watering of lawns.

With these objects in view, as well as other objects which will appear in the course of the specification, reference will be to the drawing, wherein:

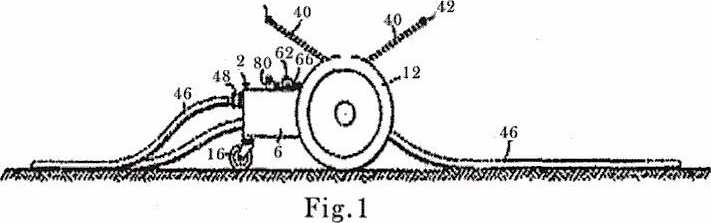

Fig. 1 is a side elevational view of a lawn sprinkler embodying the present invention, shown in operative relationship to a water supply hose,

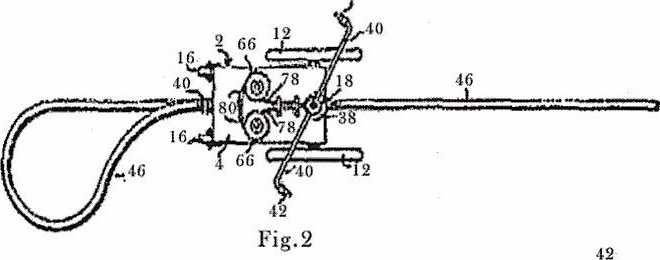

Fig. 2 is a plan view of the parts as shown in Fig. 1,

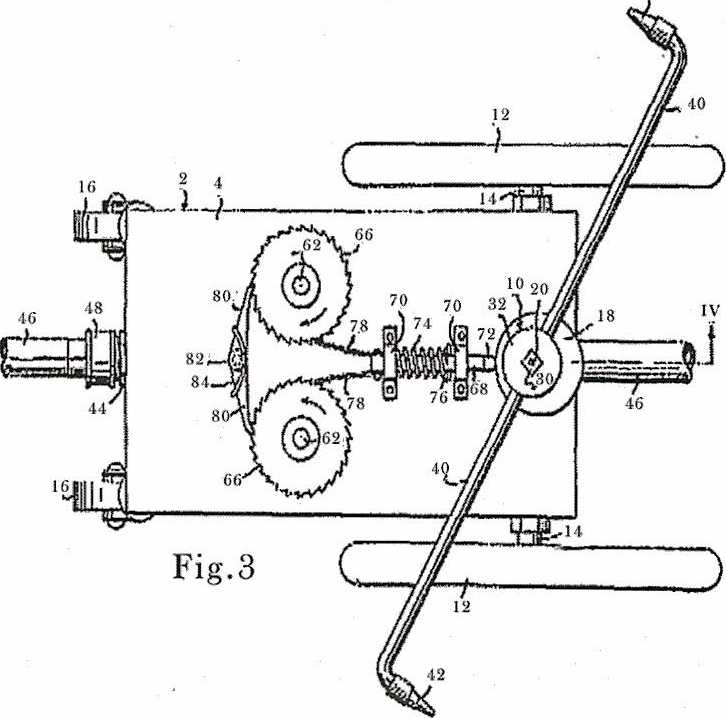

Fig. 3 is an enlarged plan view of the sprinkler,

Numerals 22,26,28,34,36,50,52,54,56,58 &.60 mentioned in the description are not shown in the figures.

Like reference numerals apply to similar parts throughout the several views, and the numeral 2 applies to a frame formed of sheet metal and having generally the form of a hollow rectilinear box. It has a top wall 4 and depending side walls 6, front wall 8, and rear wall 10, and is open at the bottom. It is supported at each of its forward corners by a ground engaging wheel 12 rotatably mounted on a stub axle 14 fixed in the adjacent side wall 6, and at each of its rearward corners by a caster wheel 16, whereby the frame is rendered steerable.

Carried on top wall 4 of the frame, adjacent the forward edge thereof, is a sprinkler head 18. Said sprinkler head includes a vertical tubular body member 20 closed at its upper end and threaded at its lower end to a pipe 22, extending upwardly through said wall. Said body and pipe are fixed relative to the frame by a nut 24 threaded on said pipe below wall 4. Body member 20 is provided adjacent its upper end with a plurality of apertures 26, and at its upper end with a threaded axial extension 28, mounted rotatably on said extension and secured thereon by nut 30, is an inverted cup-shaped member 32 the depending skirt of which is disposed concentrically about body 20 and is of larger diameter than said body member whereby to form a chamber 34 there between. At its lower end member 32 is provided with a sealing ring 36 which engages body member 20 to seal chamber 34, and with an external circular flange 38 which is disposed eccentrically to the axis of body member 20. Flange 38 serves as a cam as will be fully described below.

Fixed in the skirt portion of member 32, in communicating relation with chamber 34, are a plurality of upwardly and outwardly inclined tubes 40; at the outer end of each of which is mounted a nozzle 42. It will be noted in Figs. 2 and 3 that the nozzles are angled to direct streams of water substantially tangentially to the orbit of the nozzles, in the same relative angular direction. Hence when water under pressure is delivered to sprinkler head 18 through pipe 22, it passes outwardly through holes 26 of body 20 into chamber 34 and hence through tubes 40 to nozzles 42. There active force of the streams leaving the nozzles causes cup 32 of the head to rotate, this rotation being clockwise as shown although the direction of rotation is immaterial.

This rotation distributes the water evenly over a relatively large ground area, and also causes rotation of cam flange38, which operates the frame propelling mechanism to be described below.

Pipe 22 extends horizontally and rearwardly just below frame wall 4 and extends through rear wall 10, being secured therein by a pair of nuts 44. A flexible water supply hose 46 is secured to the outwardly extended end of said pipe by a suitable coupling 48; the hose is then looped as shown in Figs. 1 and 2 and passed beneath the frame 2 parallel to the line of travel thereof. The hose is then lifted from the ground and laid over a pair of rollers and 52 carried rotatably at the inner face of rear wall 10 and front wall 8 respectively, said rollers being mounted on axles fixed to said frame walls by brackets 54. Said rear and front frame walls are each provided with an inverted J-shaped notch 56 through which the hose may be moved transversely to engage the associated roller, and which serves to hold the hose centered over said roller.

Intermediate rollers 50 and 52, the hose is gripped between a pair of drive wheels 58, each of said wheels having a thick soft rubber facing 60 whereby to grip the hose frictionally. The drive wheel faces are concave whereby to conform closely to the hose. However, the wheel facings are sufficiently yieldable that the hose may be crowded there between. Each of the drive wheels is fixed on a vertical shaft 62 which extends upwardly through top frame wall 4 and is journalled in a bearing member 64 affixed to said frame wall. To the upper end of each of shafts 62, above wall 4, is affixed a ratchet wheel 66.

Ratchet wheels 66 are operated by a cam follower mechanism including a bar 68 disposed horizontally above frame wall 4 and carried slidably in a pair of brackets 70 fixed to said frame wall. Said bar is movable longitudinally along a line intersecting the axis of sprinkler head 18 and passing between ratchet wheels 66. It is provided at its forward end with an upright finger 72 which bears slidably against the rim of flange cam 38 of the sprinkler head, and which is urged slildably against said cam by a coil spring 74 encircling bar 68. Said spring bears at one end against one of brackets 70, and at its opposite end against a pin 76 inserted transversely through bar 68. At its rearward end, a pair of leaf springs 78 is affixed to bar 68, and extend rearwardly therefrom. Said springs extend between ratchet wheels 66, and are tensioned outwardly so that each spring engages in the teeth of one of the ratchet wheels, as best shown in Fig. 3.

Thus it will be seen that as sprinkler head 18 rotates as previously described, cam 38 thereof will rotate and urge cam follower bar 68 rearwardly against spring 74, and leaf springs 78, acting as pawls, will turn ratchet wheels 66 in the direction indicated by the arrows in transversely to ride over the ratchet teeth as the bar 68 is moved rearwardly by spring 74. The rotation of ratchet wheels 66 of course also turns drive wheels 58, and since the drive wheels are in frictional engagement with the hose, the frame is pulled forwardly along the hose. The hose may be laid out on the ground ahead of the sprinkler in any desired pattern, so long as any curves therein are of sufficiently large radius, and the frame will follow the hose. In this manner, even an irregularly shaped lawn may be watered thoroughly and evenly without necessity of attendance on the sprinkler.

It has been found that the work which must be performed by the frame in lifting the hose from the ground applies a braking force to the frame sufficient to prevent the frame from coasting forwardly by gravity, which could occur if the ratchet wheels overran the pawls 78, on any slope usually encountered in lawns. The ratchet wheels are secured against following pawls 78 on their retracting stroke, which could otherwise occur particularly on up slopes, by a pair of dogs 80 pivotally mounted on a bolt 82 fixed in frame wall 4 and engaging respectively the two ratchet wheels 66 (Fig. 3). Said dogs are urged yieldably into engagement with said ratchet wheels by a coil spring 84 disposed on bolt 82 and having its end portions extended to engage said dogs intermediate their ends.

Part C2

1 X 30 M = 30 marks

A client meets you and provides technical information regarding his invention. Draft a complete specification (with at least one claim and title) for any one of the following descriptions, for filing in the Indian Patent Office.

While preparing the complete specification, do not redraw the figures. However, you may refer to the figures in the specification as Fig. 1, Fig. 2 and Fig. 3 etc.

Q.10

This invention relates to a composition and oral pharmaceutical dosage form for selective delivery of drugs to the colon. More particularly, the invention relates to compositions and oral pharmaceutical dosage forms for release of biologically active ingredients in the colon while avoiding or minimizing release into the upper gastrointestinal tract, such the stomach and small intestine.

Numerous drug entities based on oral delivery have been successfully commercialized, but many others are not readily available by oral administration, which are incompatible with the physical and/or chemical environments of the upper Gl tract and/or demonstrate poor uptake in the upper Gl tract. Due to the lack of digestive enzymes, colon is considered a suitable site for the absorption of various drugs. However, colon drug delivery is hardly achieved in that the oral dosage form should pass through the stomach and small intestine, where many drugs are deactivated by their digestive materials.

Ideally, a colon specific drug delivery system is designed such that it remains intact in stomach and small intestine but releases encapsulated drugs only in colon. CSDS system is useful in administering a drug that is an irritant to the upper Gl tract, such as non-steroidal anti-inflammatory agents, or drugs that are degraded by gastric juice or an enzyme present in the upper Gl tract, such as peptide or protein. Further, the colonic drug delivery system allows local, direct treatment of colonic disease, e.g., ulcerative colitis, Crohn’s disease, or colon cancer, thus reducing the dosage of the drugs and minimizing undesirable or harmful side effects. Similarly, colonic drug delivery is useful for administering drugs, e.g. non-steroidal anti-inflammatory drugs (NSAIDS), which are irritants to the mucosa of the upper gastrointestinal tract such as the stomach or small intestine.

Recently, it is believed that colonic drug delivery systems maintain the efficacy of drugs for a longer time and increase the bioavailability of the drugs as compared to other oral routes of administration. As the colon has a longer retention time, drug absorption is prolonged, and total bioavailability is increased. The present invention comprises a mixture, prepared at a pH of about 7 or above, without use of a cross-linking agent, of a galactomannan and a polysaccharide, preferably pectin, selected from the group consisting of pectin, derivatives of pectin, and mixtures thereof. The composition forms a strong elastic gel that is not appreciably dissolved or disintegrated in gastric or intestinal fluids, thus protecting drugs from being released in the upper Gl tract. When the composition arrives in the colon, the composition is easily degraded by synergic effect of pectinolytic enzymes and glactomannanase, thus releasing drugs rapidly in the colon. The ratio of the two polysaccharides determines the rate of enzymatic degradation of the composition and disintegration of dosage form through Gl tract, which in turn enables the composition to release the drug site specifically in the colon.

The pharmaceutical composition of the present invention comprises an effective amount of a drug, diagnostic reagent, or mixture thereof, and a polysaccharide mixture formed in an aqueous medium at a pH of about 7 or above of (a) a polysaccharide selected from the group consisting of pectin, derivatives of pectin, and mixture thereof, and (b) galactomannan, without use of a cross-linking agent. The drug is an antimigraine, antinauseant, antineoplastic, antiparkinsonism, antipruritic, antipsychotic, antipyretic, antispasmodic, anticholinergic, sympathomimetic, xanthine derivative, potassium channel blocker, calcium channel blocker, beta-blocker, alpha-blocker or other drugs.

The weight ratio of polysaccharide: galactomannan is from about 50:50 to about 99.9:0.1 in the composition. The weight ratio of polysaccharide:galactomannan is from about 66.6:33.4 to about 90:10.

The drug as used in the pharmaceutical composition may be selected from the group consisting of mesalamine, balsalazide, olsalazine, ibuprofen, prednisolone, dexamethasone, budesonide, beclomethasone, flucticasone, tioxocortal, hydrocortisone, metronidazole, cyclosporin, methotrexate, domperidone, 5-fluorouracil, bisacodyl, senna, insulin, vasopressin, growth hormones, colony stimulating factors, calcitonin, immunoglobulin, glibenclimide, diltiazem, verapamil, nifedipine, captopril, benazepril, enalapril, theophylline, naxopren, diclofenac, acyclovir, omeprazole, lovastatin, alendronate, desmopressin, metformin, metoprolol, cisapride, tacrine, mixtures thereof and probiotics.

In the pharmaceutical composition of the invention the drug, diagnostic reagent, of mixture thereof may be used in the form of a tablet, a pill, a seed, or a capsule formulation and may be coated coated with said polysaccharide mixture to form a coated formulation. The coating may be 1-100 mg/cm2in size. In a preferred embodiment the coating is 1-40 mg/cm2 in size.

The drug, diagnostic reagent, or mixture thereof is encapsulated with a shell composed of said polysaccharide mixture to form a hard capsule formulation. The said shell is 1-100 pm in thickness. Most desired thickness of the shell is 1-40 pm in thickness.

A method for preparing the colon selective pharmaceutical composition for oral delivery of a drug, diagnostic reagent, or mixture thereof comprising forming a polysaccharide mixture in an aqueous medium at a pH of about 7 or above of (a) a polysaccharide selected from the group consisting of pectin, derivatives of pectin, and mixtures thereof, and (b) galactomannan, without use of a crosslinking agent, and contacting the polysaccharide mixture with a drug, diagnostic regent or mixture thereof.

OR

Q.11

The present invention relates to a cycle tyre tool and more specifically to a tool for removing tyres from the wheels of cycles namely monocycles, bicycles and tricycles . Tyres are normally removed from cycle wheels by means of three tyre levers which are used to lever the bead of the tyre over the rim of the cycle wheel. A problem arises in the use of tyre levers for this purpose in that there is a very real danger of trapping the inner tube between the lever and the bead of the tyre and thus damaging the inner tube.

The object of the present invention is to provide a tool that enables tyres to be removed very readily while assisting in avoiding damage to the inner tube.

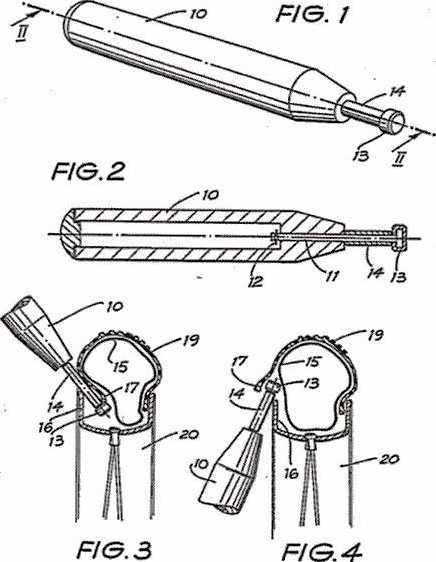

Fig. 1 is a perspective view of a tool according to the invention;

Fig. 2 is a longitudinal section thereof showing the parts of the tool; and Figs. 3 and 4 illustrate the manner in which the tool is used.

The tool, in a preferred form, consists of a handle 10 into which fits a shaft 11. The shaft 11 is free to rotate in the handle 10 but is restrained against axial movement by the press-on claw clip 12. At the free end of the shaft is a roller member 13 that is fixed at the end of the shaft 11. On the portion of the shaft 11 projecting from the handle 10 is a sleeve 14 that is rotatable on the shaft 11.

In an alternative construction (not illustrated) the sleeve 14 is omitted and the roller member 13 is rotatably mounted on the shaft 11. In use for removing a tyre the tool is held in the hand of the user and the roller 13 is inserted between the rim of the wheel and the bead of the tyre, as shown in Fig. 3, after the inner tube 15 has been fully deflated. The blunt end presented by the roller 13 serves to push the inner tube 15 out of the path of the tool as it enters between the rim and the bead.

Once the tool is fully entered the handle is depressed, as shown in Fig. 4, so that the bead 17 is forced upwardly and outwardly in relation to the rim. The tool is then rolled around the circumference of the rim 16 with the sleeve 14 resting on the rim 16 and the roller 13 resting against the inside of the tyre 19 adjacent the bead 17 (as shown in Fig. 4). It will, however, be appreciated that the sleeve 14 and the roller 13 will be rotating at different speeds due to their making contact respectively with the rim 16 and the tyre 19 at different distances from the centre of the wheel 20. It is thus necessary that the sleeve shall be rotatable relative to the handle and the roller 13 rotatable relative to the sleeve.

The tool may also be used for replacing the tyre by reversing the steps described above after slightly inflating the inner tube 15.

Refer to the official website for the latest question papers : http://www.ipindia.nic.in/Patent-Agent-Examination.htm